LARGE PROJECTS & BUILDS

Lake Control Spillway Gates

A large acrylic scale model of a set of lake level control gates and spillway structure, acrylic work designed and fabricated by Kirby Carbon to match existing real world dimensions of the structure.

Kirby Carbons responsibilities on this job included, project management, CAD design of acrylic model, CNC fabrication of entire structure, 3D printing of gate opening mechanisms, and construction of all upstream and downstream components.

Dam Spillway Scientific Build

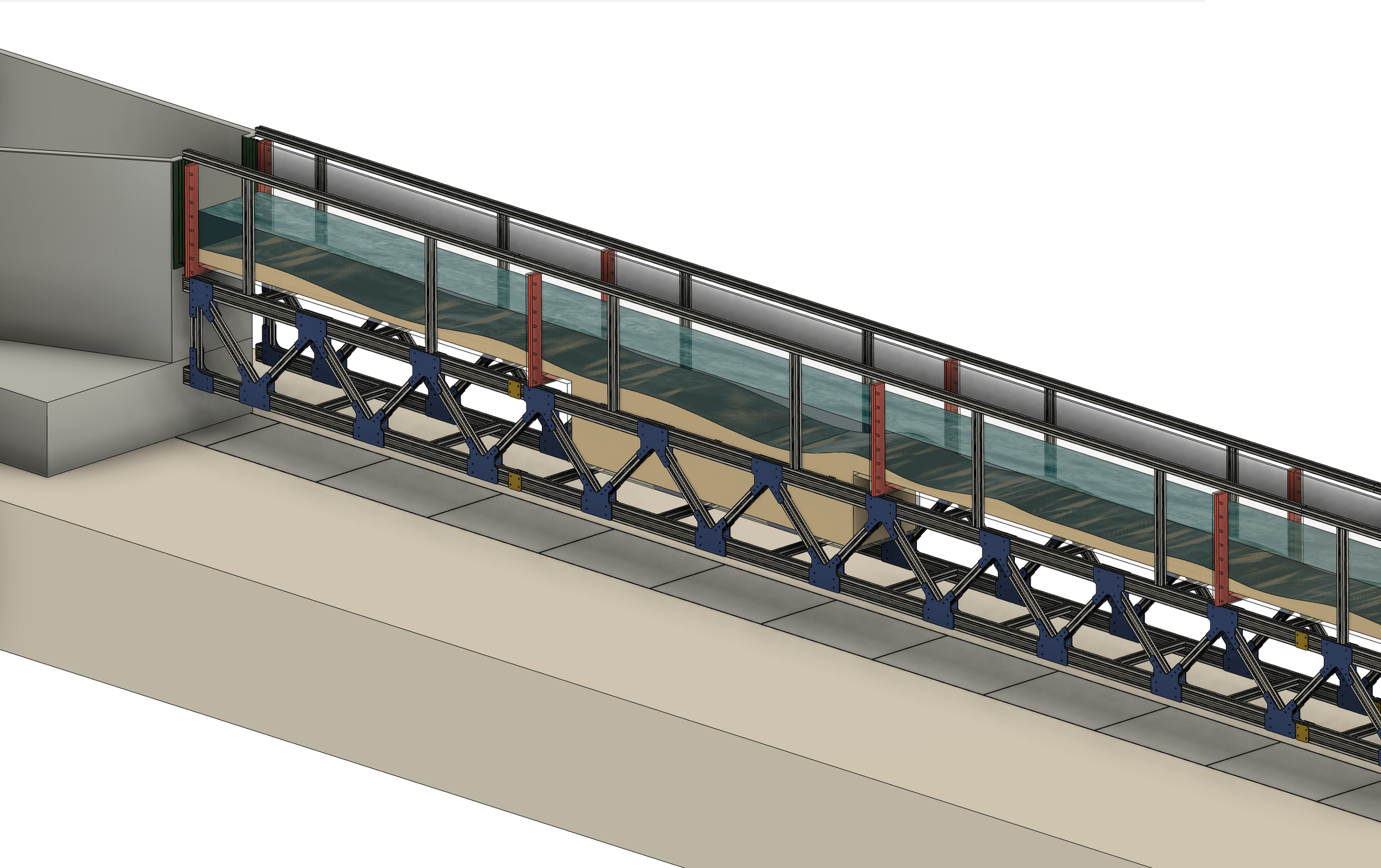

A large acrylic scale model dam for water flow testing with opening gates and many small details over the complete 16 meter length of the build. Modelled off an existing dam at 1:25 scale Kirby Carbon was responsible for the complete acrylic design and fabrication of the project including the supporting frame. Notable features of the build are the complex gate structure and tailrace bathymetry based of a real world 3D scan.

This model will have 200+ litres of water go through it every second so the design was crucial to ensuring a strong robust test rig for the many months of testing this model undergoes

Mclaren F1 LM Replica Homage Parts

Faithfully replicated parts from world famous the 1996 Mclaren F1 LM, this project required a lot of reference gathering and research to accurately replica the parts using only information and images available online.

Many other parts from the F1 were designed along side these parts.

A waterproof aluminium housing for a small pressure sensor. This job had many dimensional constraints which required a very accurate 3D model to ensure fits. Along the design pathway Kirby Carbon used 3D printing to validate designs and tolerances in the project.

This job had full engineering drawings produced by Kirby Carbon and was sent to en external manufacturer for production.

Pressure Sensor Housing

Lotus Exige refresh and Upgrade

Complete interior and exterior refresh of a 2009 Lotus Exige. Kirby Carbon completed a refresh on the car along with installing new Ohlins shocks and several custom fabricated pieces all of which were design in house by Kirby Carbon.

Carbon Fibre Seatbelt Cover

A cosmetic carbon fibre seatbelt cover which was designed to neatly fit overtop of existing buckles installed in current day performance cars like the Lamborghini Hurucan and Ferrari F8.

These covers are made from a 3D printed carbon fibre reinforced nylon plastic then covered with real carbon fibre and then painted to customer requirements.

Spillway tunnels and Crest

A large scale model dam build which Kirby Carbon was involved with the initial consulting, assembly, and testing phase of the project.

Kirby Carbon designed and manufactured the reservoir tank baffling for this project. The importance of the baffling is to provide smooth even water flow to the model during testing.

A replica scale model of a river section in a residential area prone to flooding, details include a removable bridge section, dynamic river bed, and tunnel modifications.

Kirby carbon project managed the build, along with all design and fabrication work. To create the river form 3D scan data was used to create a set of profiles that follow the river, these were CNC cut out and formed the guide for the top mortar layer.

Dynamic River modelling

Proposed Bridge Design Study

Testing of a new bridge pier design in a dynamic bed test setup. This model is primarily made of 2 bent sheet metal components for the entire bridge deck and CNC acrylic piers with 3D printing brackets to hold sensors.

The project had an alternative setup which uses 3 load cells mounted to the surface of the bridge, to mount the load cells complex 3D printed brackets were designed and fabricated by Kirby Carbon

CAD Design Projects

New scientific reciprocating flume design by Kirby Carbon, This design used a modular construction method using aluminium profile and laser cut jointing brackets.

On top of the modular frame sits sectional Acrylic channels which bolt together to form the main part of the flume, a channel in the floor was utilised to hold the return pipe which has the benefit of lower the height of the flume off the floor.

CAD Flume Design

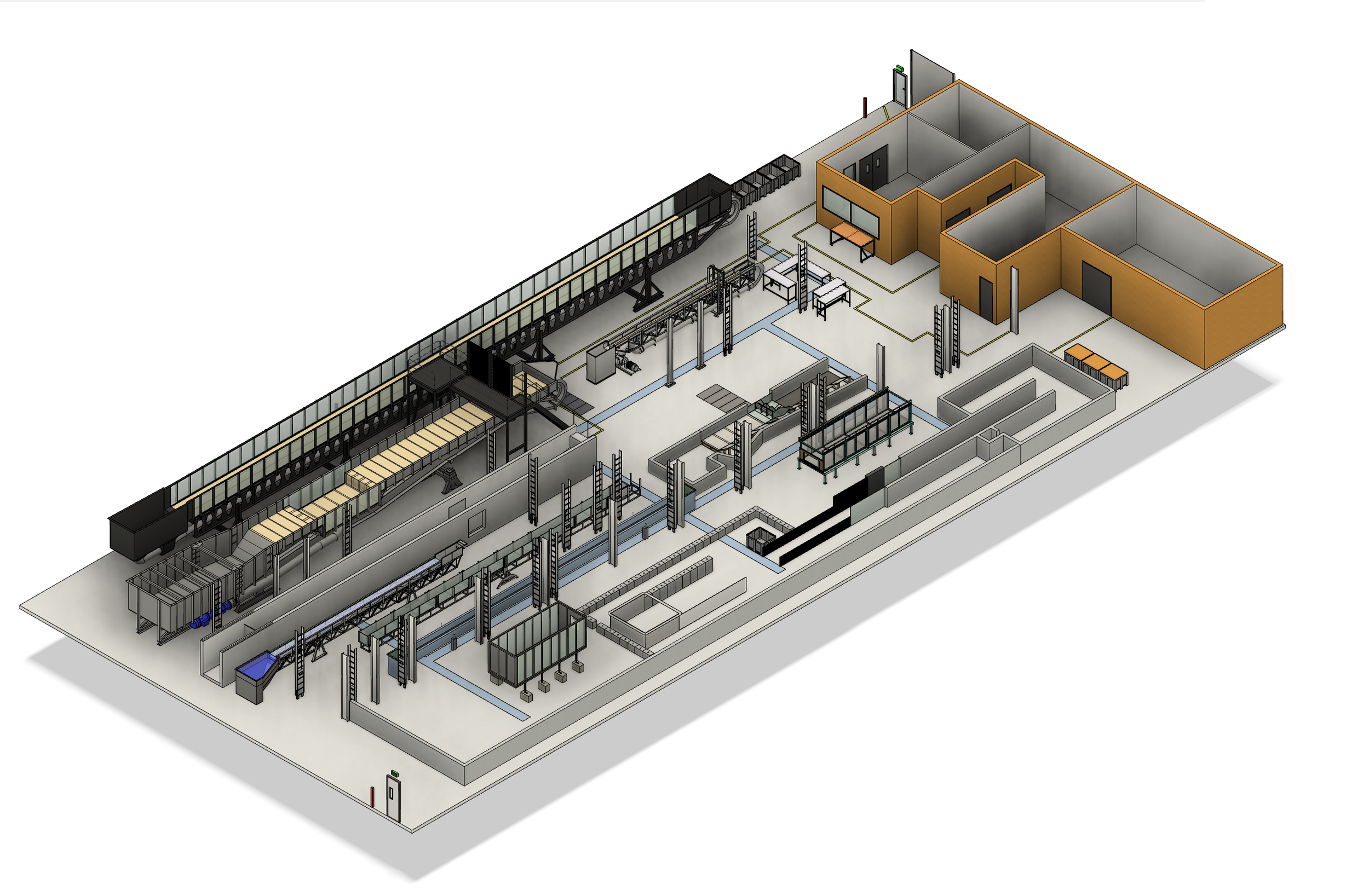

Large Scale Reverse Engineering

Using real world measurements and 3D scanning to create a large detailed model of an entire laboratory work place. This will aid in any future development plans for the company as they can quickly and easily visualise new projects within their existing floor space.

Kirby Carbon completed this model to a very highly detailed level to ensure maximum accuracy and therefore maximum usability of the completed model.

Modelling of a V12 BMW engine cam cover using a 3D scan of the original part.

Kirby Carbon scanned the original part imported the scan into cloud mesh software, exported a cloud mesh into fusion 360 and then modelled the new parametric part using the scan.

For a large complex part like this with many curves a scan is usually the only way to get an accurate representation of the part. Now with the part parametrically modelled it can be modified.